top of page

Sea Machines Robotics

Overview

I am currently working at Sea Machines Robotics, a company that makes marine autonomy systems and unmanned surface vessels (USVs). As a Systems and Applications Engineer at SMR, I handle hardware design/validation, sensor integration, and upgrading testing infrastructure for marine autonomy. I also work on computer vision, ensure compliance with regulatory bodies, author PLC code, manage CAD and BOM revisions, and supervised an intern.

Additional Accomplishments

SMR's test vessel Maverick and USV Stormrunner

The SM300-SP

SMR's flagship product is the SM300 autonomy cabinet, which can be connected to any vessel's CAN busses, radar, steering, and engines to convert it into an autonomous vessel. I designed, built, and validated the company's next generation autonomy cabinet, the SM300-SP. This involved several key steps:

.png)

Autonomy Computer Selection

Comparing industrial computers to balance computing power, power draw, form factor, and ruggedness.

Electrical Schematic

Defining electrical connections, fuses, and connector pinouts.

Mechanical Top Level Assembly

Creating a CAD model to lay out each component, focusing on ease of assembly, heat management, and repairability.

Prototype Build

Putting my CAD model and electrical wiring diagrams into the real world!

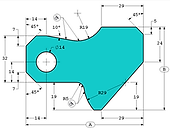

Manufacturing Hardware Drawings

Specifying dimensions and tolerances for the machine shop.

Testing & Validation

Running the system with our test vessel Maverick, integrating with our simulators, and performing environmental testing at a lab.

I am also working on building the factory validation system which will automatically check IO/CAN/serial/ethernet connectivity and load default configurations once these units are in production!

MFAK

The Maritime Flyaway Autonomy Kit (MFAK) is designed to convert virtually any small vessel into a USV, prioritizing speed and affordability. When time is of the essence, simplicity is key. I worked to ensure that every connection lined up, every instrument communicated properly, and streamlined the deployment process.

Our team of 5 worked tirelessly to convert a 13ft Boston Whaler (60hp) into a USV, with a total work time of 20 hours for the first deployment.

This entailed:

- Removal of original power and steering

- Wiring new power system

- Mounting & connecting equipment

- Calibrating sensors & actuators

- Networks setup and troubleshooting

- On-shore IO and engine test

- Sea trial

What I did specifically:

We were able to demonstrate remote control and full autonomy on the water in Winthrop, MA.

As a testament to our iterative design, each new deployment of the MFAK system takes increasingly less time. I continue to work with the field team, manufacturing dept., and vendors to simplify the design, lower BOM cost, and achieve faster deployment speeds.

comprehensive redesign of the connections between each component

Stormrunner

In January of 2025, SMR set out to design and build its newest USV, Stormrunner. Once the onboard equipment was selected, I created the top-level assembly for components within the electronics bay, laying out how each item would be mounted. I also performed power draw and weight distribution calculations. In February I was appointed Technical Lead for the project, responsible for coordinating technical tasks between members of the team as well as collaborating with the shipyard engineers to ensure the build went smoothly.

Along the way, I managed the CAD model and BOM, integrated our computer vision system, troubleshot sensor/comms/networking/electrical issues, worked on the VOIP system, and successfully delivered a full vessel within 6 months.

AI-ris

SMR's maritime computer vision system, AI-ris, is used to passively identify vessels in the vicinity. It can assist the autonomy system by sending TTMs or working as a standalone product. It is capable of discerning between powered and sail vessels, calculating its distance and bearing, and flagging marine life. Its optional thermal camera allows for usage in low-visibility conditions.

Getting precise range estimation is no easy feat. Firstly, the image from the camera's fisheye lens needs to be "flattened out" in order for the machine learning model to identify objects. This is achieved by using an April grid in a process called "camera calibration". The system identifies key features in the April grid and reprojects them into the correct planar position. Error induced in this process is known as "reprojection error", measured in pixels.

Credits: MathWorks

Example April Grid

Reprojection error is a key metric in camera calibration, because it is a measure of how far off a reprojected pixel is from its correct position. When looking at vessels up to 2km away, every pixel can represent hundreds of meters, and reprojection error of only a few pixels can make your range estimate very inaccurate.

Credits: camcalib

Together with my intern, we worked with the machine learning team to refine our camera calibration procedure, reducing reprojection error from ~20 pixels to <1 pixel.

Another important piece of range calculation is the horizon estimation. This is complicated by many factors, such as atmospheric refraction, the motion of the vessel, and landmasses in front of the horizon. In order to stabilize the video feed, we opted to integrate a gimbal.

The gimbal we chose was not IP-rated, so I worked with an engineering firm to create a custom watertight enclosure for the gimbal. We needed to determine the maximum range of motion of the camera/gimbal assembly during Sea State 5.

Knowing that the maximum wave height for Sea State 5 is 13ft, and that a wave typically breaks when the wave steepness is greater than 1/7, the minimum wavelength will be 91ft. Graphing the wave and finding the slope at the inflection point of the curve yields the maximum pitch experienced by the vessel, which is 25.714 degrees.

With the improvements in camera calibration and integration of a gimbal and watertight enclosure, we were able to achieve <10% passive range accuracy with AI-ris. Alongside these improvements, we have been exploring other camera options (rectilinear lenses, different resolutions, different compression formats) and processor hardware upgrades.

Testing Infrastructure

Aside from my responsibilities on specific projects, a core component of my role at SMR is maintaining and upgrading testing infrastructure. SMR's test vessel Maverick, alongside a fleet of simulator vessels, allow software engineers to stress test their code before packaging it into a new release.

I select and install new sensors and equipment on Maverick, such as GNSS, speed through water (STW) sensors, autonomy systems, and cameras.

I also keep up-to-date documentation for the onboard equipment, help our captain maintain the vessel, and work with engine technicians to enable new autonomy features.

The simulators are autonomy systems that aren't hooked up to a physical vessel. They are fed simulated position, speed, and engine data to complete the feedback loop. I perform upgrades and maintain documentation to keep all of them in working order.

Fun fact: All new simulators are named after sea monsters!

Additional Accomplishments

At SMR, I also worked with Real Time Kinematic (RTK) sensors for positioning data with centimeter-level accuracy. This proved helpful later on when I integrated an Inertial Navigation System (INS) to test GNSS-denied autonomy. This required writing Python code to parse the byte packets from the INS, then formatting my own byte packet to send STW data back to the INS.

I worked in tandem with a large client and the American Bureau of Shipping (ABS) to successfully deliver a class-approved implementation.

I authored PLC code for parsing and handling NMEA2000 engine alarms.

I created an analog IO calibration function for our internal tool using Python and TIA Portal.

I created slideshows to improve onboarding of new engineers.

What I Learned

Software

Hardware

Other

-

PLC code

-

Docker containers (Balena)

-

Serial communication

-

Networking

-

Camera calibration

-

NMEA2000

-

Onshape

-

Computer selection

-

GD&T

-

Vibration isolation

-

Power distribution

-

Hydrodynamics

-

Diesel engine maintenance

-

Gimbals

-

Personnel management

-

Maritime safety

-

Working with regulatory bodies

-

RTK/INS sensors

-

Product Lifecycle Management

bottom of page