top of page

Piaggio Fast Forward

Overview

For my second co-op, I worked at Piaggio Fast Forward as a Manufacturing Engineering Co-op. I developed automated tests for quality control and inspection, analyzed testing data, and managed reliability testing. I also coordinated with the mechanical, electrical, and software teams to ensure critical data was being collected from the manufacturing line.

Role

Manufacturing Engineering Co-op

Team

Cross-functional

Course

Co-op #2

Duration

Jul. - Dec. 2022

Overview

For my second co-op, I worked at Piaggio Fast Forward, a company that makes cargo-carrying robots with smart-following technology. As a Manufacturing Engineering Co-op, I developed automated tests for quality control and inspection, analyzed testing data, and managed reliability testing. I also coordinated with the mechanical, electrical, and software teams to ensure critical data was being collected from the manufacturing line.

Role

Manufacturing Engineering Co-op

Team

Cross-functional

Course

Co-op #2

Duration

Jul. - Dec. 2022

Overview

For my second co-op, I worked at Piaggio Fast Forward as a Manufacturing Engineering Co-op. I developed automated tests for quality control and inspection, analyzed testing data, and managed reliability testing. I also coordinated with the mechanical, electrical, and software teams to ensure critical data was being collected from the manufacturing line.

Role

Manufacturing Engineering Co-op

Team

Cross-functional

Course

Co-op #2

Duration

Jul. - Dec. 2022

Automated Testing

In order to understand process capability and assembly variation of production subassemblies, I needed to establish a performance baseline. To start, I read the documentation, analyzed the dynamics of the subassembly, and talked with the mechanical engineering team. Then, working with Python in a Linux environment, I utilized the proprietary software within the gita robots to create an configurable automated test that measured subassembly performance for both the gita+ and the gita mini.

Using the same PID controls that the robot operates with, I was able to reduce signal noise by up to 80% and reveal data trends. This data helped me to identify several faulty units on the production line before they were installed into the final product. I also simulated common failure modes in the subassemblies to recognize how they would affect the test data. This enabled the customer support team to conduct quick diagnosis of field issues.

Before

After

Data visualization for a production subassembly. In compliance with NDAs, relevant information has been redacted.

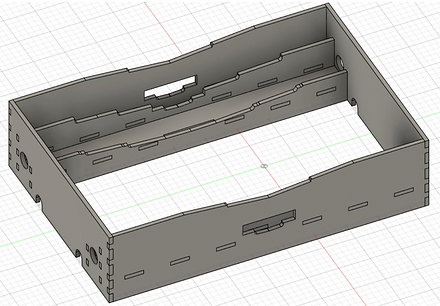

To support this automated test, I designed a serialization system to keep track of each subassembly unit and maintain a record of its performance. I used Fusion360 to design a test fixture which would fit both gita+ and gita mini subassemblies. Test results were automatically uploaded to the Tulip Manufacturing Execution System via an API. I also authored work instructions and created a GUI for operator use. Today, the test is a key station on the gita production line.

Serialization sticker, placed on every production gita unit

Test fixture that fits multiple product models.

Motor Inspection

A batch of 2000+ motors from a supplier needed to be inspected to ensure they were properly configured, which would have taken much time and caused significant delay to the already full inspection schedule. After exploring motor current/torque relationships, reading documentation on the motors, and consulting with the inspection team, I was able to use Python to create a performance baseline and develop an automated inspection test. I also created a GUI for operator use.

The test measured the performance of each motor and returned a PASS, FAIL, or UNSURE result. After performing a double-blind validation experiment, the automated test was found to have a 91.6% accuracy with no false results. This test dramatically reduced necessary inspection time and eliminated the need for destructive inspection.

Additional Responsibilities

Apart from developing automated tests, I managed reliability testing of the robots. This consisted of letting the robots run for hundreds of miles to examine issues that arose from prolonged usage. To monitor the testing setup, I set up a live video feed and a Slackbot with automated alerts. I performed failutre root cause analysis by examining video recordings and worked with the autonomy, electrical, and mechanical teams to identify issues and fixes.

Furthermore, I performed the following duties:

-

Reconfigured the factory floor for flow optimization ahead of 2 product launches

-

Authored Tulip work instructions and created detailed engineering drawings

-

Implemented the Tulip API on other stations, eliminating human error and reducing the number of computers needed at each station

-

Wrote detailed documentation and troubleshooting guides

-

Diagnosed and repaired faulty customer return units

-

Performed hinge fitment testing

-

Performed QA testing: following at various loads and smart behaviors

-

Worked with assemblers to compile a Master Tools List and set up tool organization at each station

-

Represented PFF at the MassRobotics Career Fair

What I Learned

-

Linux OS

-

Python

-

Tulip MES

-

PID Controls

-

APIs

-

Flux core welding

-

Cold saw

-

Fusion 360

-

Systems-level thinking

-

Greater attention to detail

-

Rapid prototyping

-

Cross-functional communication

-

Manufacturing processes

bottom of page